ABOUT

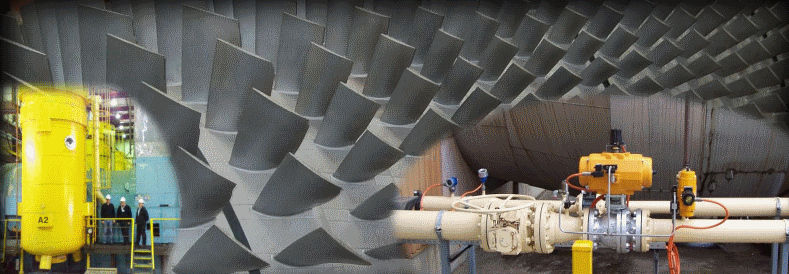

PANTAC System Control is an Australian System Integrator specialising in safety instrumented systems and critical control solutions. Our client base includes water, mining, chemical, power and the oil & gas industries.

PANTAC System Control staff and associates, total decades of experience in safety systems and rotating machinery controls. With both domestic and international work completed throughout Asia.

PANTAC System Control’s principal is a TUV Functional Safety Expert (ID 251/13), Australian EnergySafe complex gas appliance (type B) licensed and Turbine Functional Safety Certified.

PANTAC System Control provides training services for Turbine Functional Safety Competency accreditation, compressor anti-surge control and Gas Turbine Instrumentation & Control

PANTAC System Control specializes in commissioning mission critical controls including:

- Turbine safety & control

- Gas and steam turbine governor, sequence and process controls and simulation

- Safety Instrumented Systems Emergency Shutdown Systems for major hazardous facilities

- Burner Management Systems Boiler and Furnace burner management solutions complete with EnergySafe type B certification

- Compressor control Anti-surge control, load sharing, process simulation

- Generator control Automatic Voltage Regulation, AEMO compliance testing and modeling

- Man machine interface Operator and data acquisition systems

- Vibration monitoring systems for hydro, steam and gas turbine generator applications